American Fork, Utah — January 29, 2026

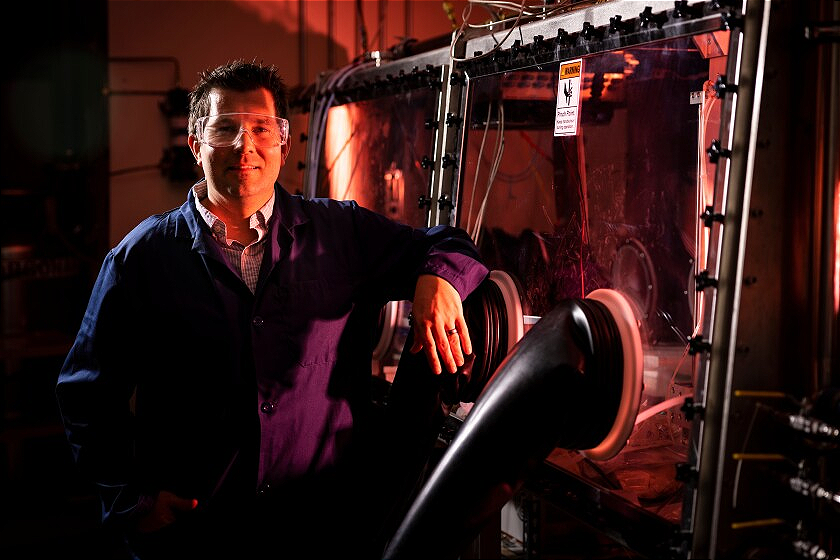

Matt Memmott, CEO of AlphaTech Research Corp., is on a mission to reshape nuclear power. From his lab in American Fork, he’s developing compact, molten salt–fueled reactors (MSRs) that are small enough to be delivered by truck, assembled in days, and efficient enough to challenge traditional utility-scale reactors. With experience spanning Westinghouse to Brigham Young University, Memmott is tackling nuclear’s biggest hurdles—cost, safety, and waste—while positioning Utah as a potential national showcase for distributed, next-generation nuclear energy.

Small Reactors, Big Potential

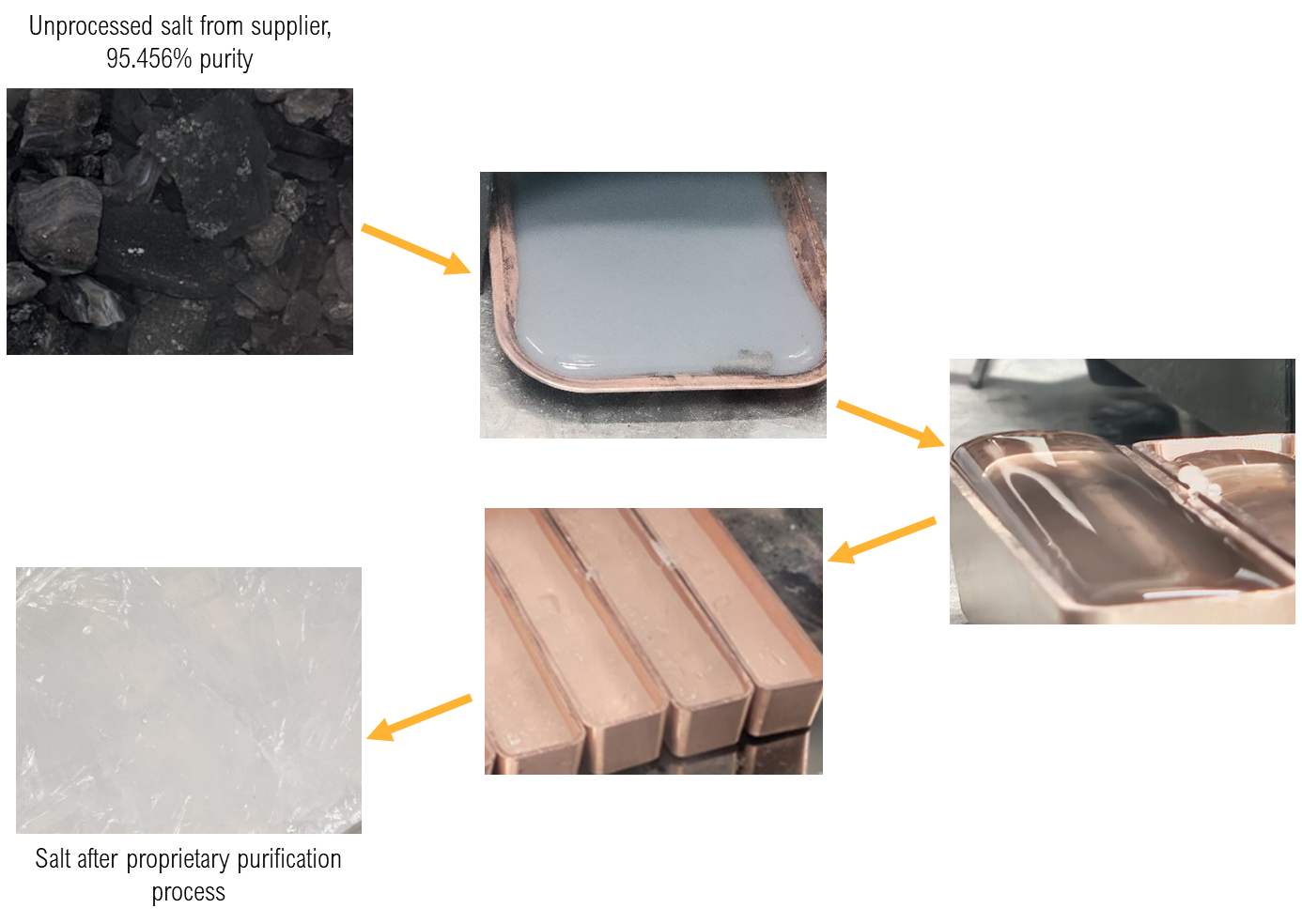

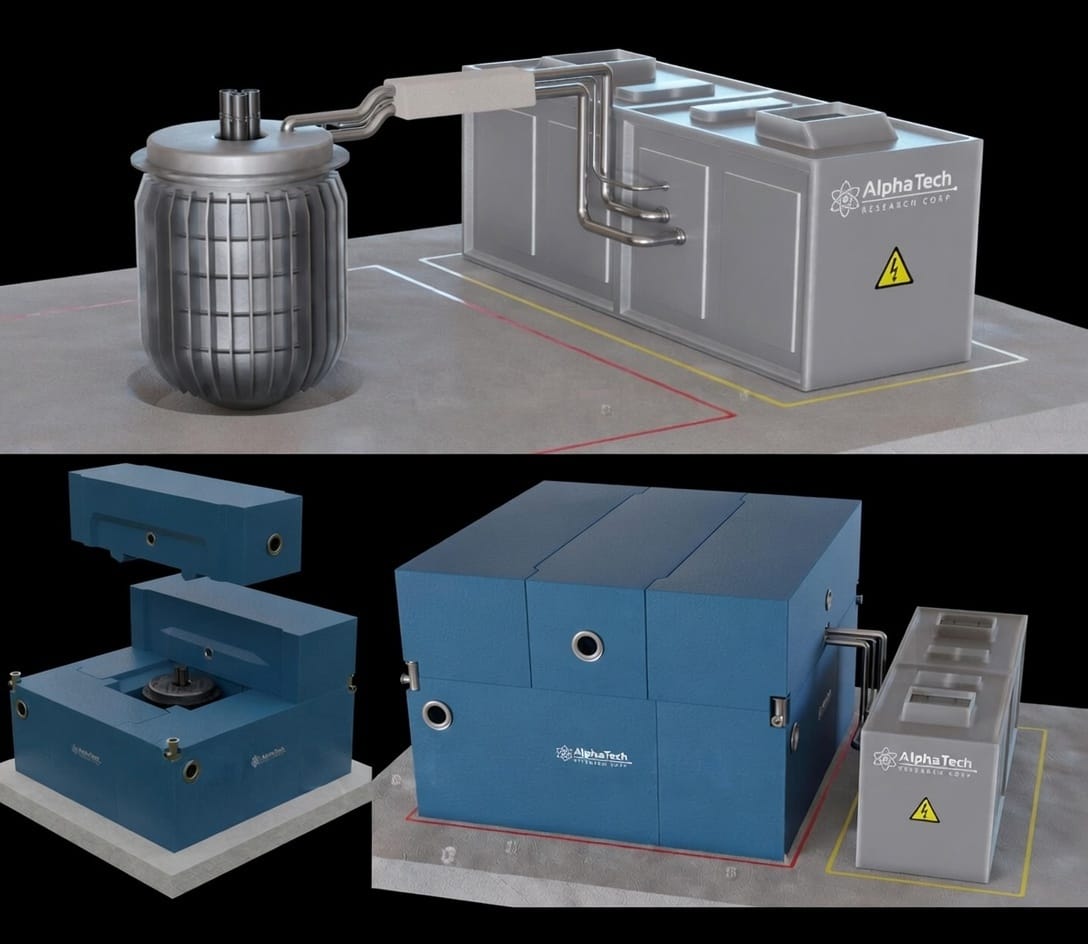

AlphaTech’s molten salt reactors measure roughly five feet wide and seven feet tall but can generate 12 megawatts each—enough electricity to power about 12,000 homes. “These are not massive plants,” Memmott says. “They’re compact, modular, and designed to be produced in a factory, shipped by truck or even a C-17, and assembled on site in about two days.”

A single reactor plant occupies just 30-by-30 feet, but up to 100 units can fit on a seven-acre facility, collectively generating 1.2 gigawatts. By designing these reactors to sit underground, AlphaTech maximizes shielding, isolates operations from public exposure, and safeguards against aircraft incidents.

Exiting the Core

Molten salt isn’t just fuel—it’s a versatile medium for heat and energy. Exiting the core of the reactor at 650°C, the coolant retains temperatures above 550°C even after generating electricity, enabling high-temperature industrial applications like chemical manufacturing, desalination, and district heating. “By the time the temperature drops to 70°C, the heat can be diverted to above-ground facilities, leaving almost no energy wasted,” Memmott explains.

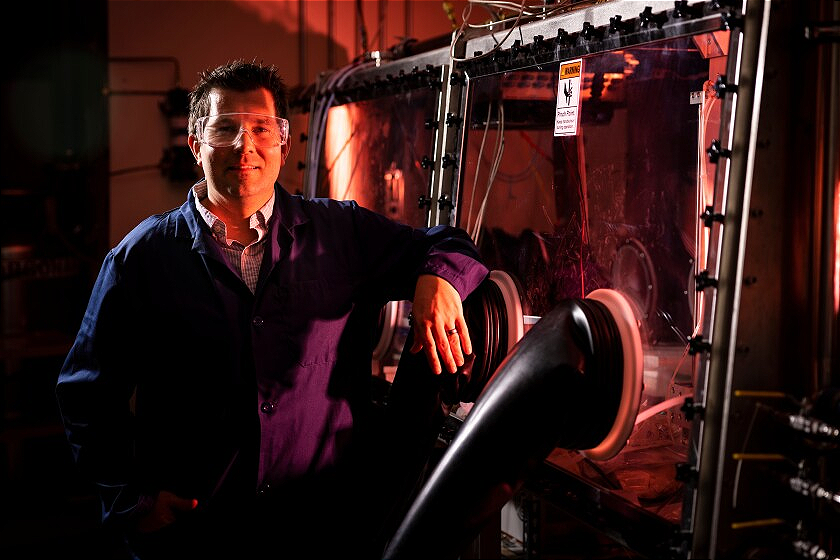

Molten salt’s corrosive nature has historically limited MSR viability. AlphaTech overcame this by purifying the salt to remove oxygen and hydrogen impurities. Untreated samples corrode nickel crucibles within hours, but treated salt maintains clarity and integrity for days. This breakthrough extends component life from five years to potentially 500, according to Memmott, dramatically reducing operational costs.

Shielding Innovation and Safety

Traditional nuclear shielding relies on heavy concrete, water, and lead. AlphaTech developed proprietary neutron-shielding technology that effectively blocks radiation while reducing weight and cost. “You could stand outside this shielding every day and still be well below radiation limits,” Memmott notes.

MSRs are also designed to be walk-away safe. In a malfunction, the system cools autonomously and freezes, preventing the risk of large-scale meltdown. Even a simulated TOW missile strike would only create a localized, solidified spray of salt, leaving the environment unharmed.

Artificial Intelligence Accelerates Reactor Design

Memmott’s approach to nuclear innovation is unconventional: artificial intelligence. But this isn’t a scenario where AI controls nuclear codes. Instead, AlphaTech leverages machine learning to solve complex reactor design challenges that would otherwise take months.

Designing a nuclear reactor involves multi-scale physics—from neutrons moving at the quantum level to coolant flow on a macro scale. Heat transfer, material behavior, and corrosion are all “tightly coupled,” meaning small miscalculations can ripple across the entire system.

“When I was at Westinghouse, it took the team of neutron guys six months just to run one of their complete-core multi-physics models,” Memmott recalls. “And if they found they had made a mistake two months in, then they just wasted two months of the valuable computational time and they would have to start over.”

Rather than replacing traditional reactor simulations—which remain mandatory under U.S. nuclear regulations—AlphaTech uses machine learning models to inform, guide, and accelerate them. The AI predicts temperature profiles based on reactor geometry and operating conditions, allowing engineers to focus high-fidelity, computationally intensive simulations on the most promising designs. In practice, this narrows an enormous design space and dramatically reduces trial-and-error. What once required months of iterative modeling can now be accomplished in days, without bypassing any required safety analysis or regulatory review.

Memmott and BYU colleagues tested a dozen algorithms, narrowing to three top performers, and refined them until they could handle preliminary datasets. Their proof-of-concept optimized a reactor shield design in just two days, where traditional methods would have required half a year.

“The speed-up is dramatic,” Memmott says. “This isn’t just about shaving a few weeks off a project. It fundamentally changes the timeline for deploying new reactors.”

The AI assists without replacing human oversight. Engineers make final design decisions and carry out safety assessments, ensuring rigorous standards while dramatically accelerating progress.

Economic Advantages and Waste Innovation

MSRs promise significant economic benefits. Fuel is roughly 400 times cheaper than advanced solid-fuel reactors. Factory-built production further reduces costs, while in-situ extraction from spent fuel creates opportunities to harvest uranium, medical isotopes like molybdenum-99, and rare earth metals—transforming nuclear waste into revenue.

This combination of low-cost fuel, modular manufacturing, and efficient design positions MSRs to compete with fossil fuels and renewable energy while providing essential baseload power.

Licensing and Utah’s Advantage

Licensing new reactors in the U.S. has historically taken 20 years and around $1 billion, excluding construction costs of $5–30 billion. AlphaTech’s factory-built MSRs offer a shortcut: by licensing the production facility, each reactor can be pre-certified, drastically reducing costs and timelines. Utah’s pro-nuclear policies, including Operation Gigawatt, further ease regulatory hurdles.

“The demand for electricity is going to skyrocket in years to come, and we need to figure out how to produce additional power quickly,” Memmott says. “The only baseload power we can make in the gigawatt quantities needed that is completely emissions-free is nuclear power. Being able to reduce the time and cost to produce and license nuclear reactors will make that power cheaper and a more viable option for environmentally friendly power to meet the future demand.”

Collaboration with Beehive Energy

Collaboration is also key. Memmott’s team has worked alongside organizations like Beehive Energy Alliance, a Utah nonprofit that connects engineers, investors, government officials, and industry leaders to modernize energy infrastructure, accelerate advanced energy solutions, and shape policy for a resilient, clean, and equitable energy future.

“Policy, regulation, and engineering talent need to come together,” says Joe Ross, Chairman & Treasurer of Beehive Energy Alliance. “Vision and intentions aren’t enough; you need technical expertise to execute.” Beehive emphasizes collaboration and transparency, helping Utah anticipate energy needs while aligning infrastructure, rules, and incentives with next-generation technology.

Timing and Market Readiness

The last decade of cheap natural gas slowed nuclear innovation, but rising energy demand and hyperscale data centers are creating new incentives. Utah’s supportive business climate, access to cutting-edge nuclear and renewable technology, and forward-looking regulatory environment make it fertile ground for AlphaTech’s reactors.

Local utilities, however, face structural limitations. Rocky Mountain Power’s transmission capacity constrains independent power projects, slowing deployment even when generation technology is ready. Legislative reforms under SB132 aim to address that bottleneck by reducing the entry threshold for independent power projects—from 100 megawatts to 50 megawatts (with some proposals landing at 75 megawatts)—and by allowing behind-the-meter transmission, changes that could materially accelerate deployment of small, distributed reactors like AlphaTech’s.

The state’s proactive stance mirrors lessons from Utah’s quantum computing ecosystem, where promising technology stalled without coordinated leadership. Beehive Energy provides that continuity, connecting technical, regulatory, and financial stakeholders before bottlenecks emerge.

A Distributed Nuclear Future

AlphaTech’s compact reactors could redefine nuclear power. With underground, transportable, walk-away safe units, the company envisions a future where clean electricity, industrial heat, and even resource recovery come from modular reactors distributed across the grid.

“Utah has the talent, resources, and political will,” Memmott says. “Now it’s about connecting the dots. If we do, we could not only transform energy production here but create a model for the rest of the country.”

By combining technical innovation, AI optimization, supportive policy, and stakeholder collaboration, AlphaTech is not just building reactors—it’s building a scalable framework for next-generation nuclear power.

As the global energy landscape evolves, Utah may emerge as a proving ground for distributed nuclear power, demonstrating that small, safe, and scalable reactors can meet the world’s growing energy demands while remaining environmentally responsible.

Learn more at alphatechresearchcorp.com.