West Valley City, Utah – June 11, 2025

Nusano, a nuclear technology firm specializing in isotope production, provided this week a preview of new first-of-its kind, 190,000-square-foot facility for media, investors, tech leaders, and invited guests. Alongside the building VIP preview tour, the company announced a significant milestone: the successful enrichment of gadolinium-160 (Gd-160) to 99.2% purity—entirely in-house.

The breakthrough, according to Nusano, underscores the company’s goal of reshoring and scaling the U.S. supply of stable and radioactive isotopes, which are essential for medical diagnostics, cancer therapies, battery technology, and emerging nuclear energy systems.

“Establishing a 100% domestic supply chain for strategic stable isotopes is another significant step toward our mission of empowering innovation,” said CEO Chris Lowe.

“Our proprietary technologies are scaling to ensure a high level of reliability and purity so our customers can grow their operations and stabilize their supply chains,” Lowe added.

Stable isotopes, like Gd-160, are used as feedstock in the production of radioisotopes. In the case of gadolinium, the natural form contains only 21.86% of the desired isotope. Nusano’s ability to enrich it to 99.2% purity “opens the door to high volume, high purity radioisotope manufacturing,” said Lowe.

At the preview tour, Lowe emphasized the broader implications of this milestone. “We can open up more of the periodic table… produce isotopes at scale… very quickly… and at a higher level of purity,” he said. “That is a game changer, because that helps ensure that our supply chain remains right here in West Valley.”

Nusano’s Director of Mechanical Engineering, Austin Yusi Cao, spotlighted the role of infrastructure in supporting this complex operation. “You're standing in really an incredibly well-designed building that we first started designing almost five years ago,” said Cao. “Every single hidden bolt in this building, that 10-ton crane—it’s all built to support the accelerator.” At the heart of the system is Nusano’s proprietary ion source. “What you're seeing is the secret sauce behind our company: creating a cloud of alpha ions that is orders of magnitude more than anyone else in the world today,” said Cao. “That's 100 times more than anyone else on the planet today,” he added. With installation nearing completion, Cao said, “In about two months, you'll see this place come alive with activity and everything installed, signaling a transformative moment for Utah’s economy and global healthcare.”

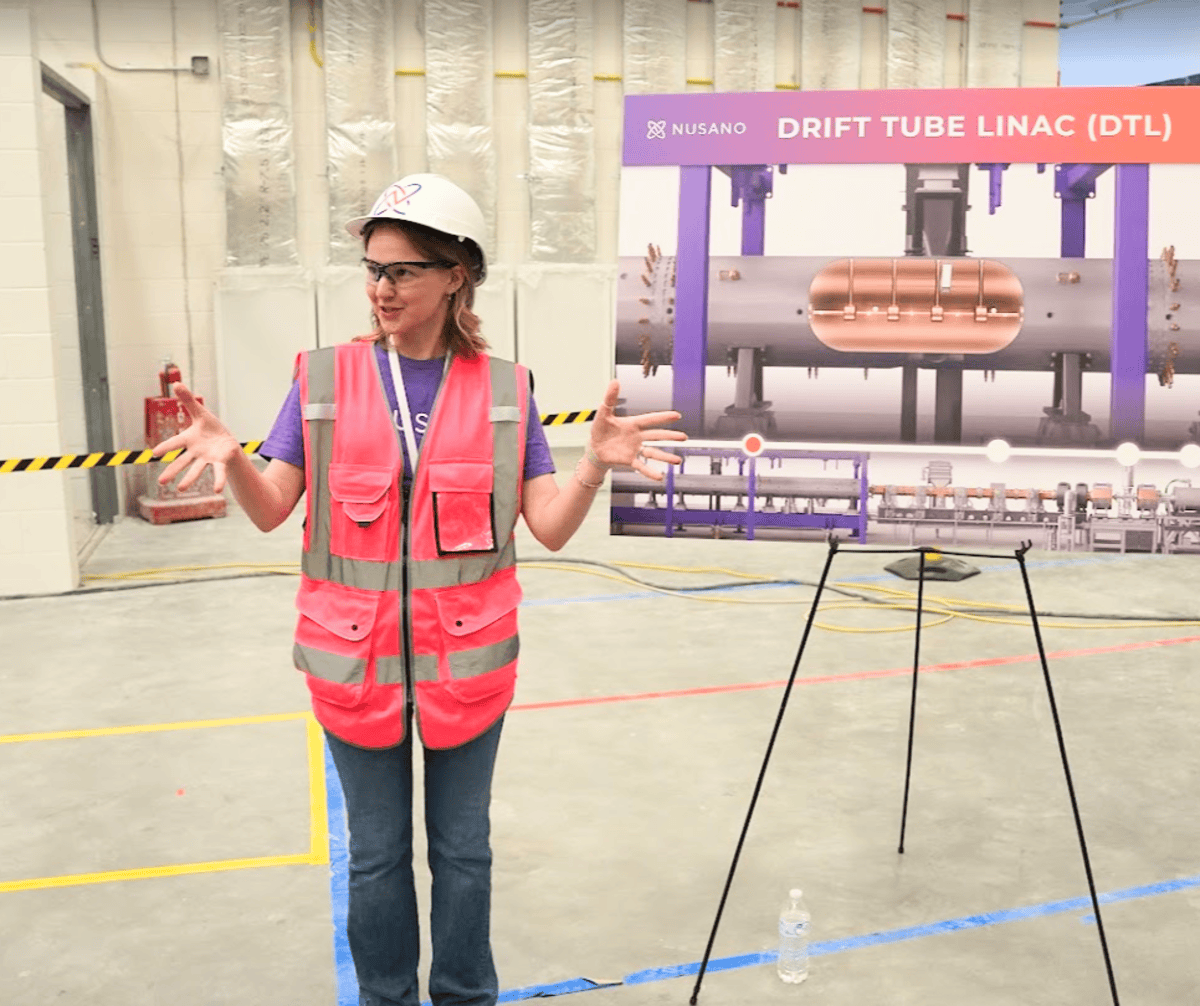

During the tour, Irina Petrushina, an Applied Physicist at Nusano, explained the company's linear accelerator (LINAC), a key component of the company's radioisotope production platform. A LINAC is a device that accelerates charged particles—such as protons or alpha ions—along a straight path using oscillating electric fields. Petrushina likened the process to particles “surfing” on ocean waves. As particles travel through a long metallic structure, known as the drift tube assembly, the oscillating fields give them momentum while the tubes shield them during deceleration phases. Embedded magnets ensure the beam remains focused, directing particles precisely at their targets to initiate nuclear reactions and produce medical isotopes. “This technology, refined since the 1940s, combines proven methods with Nusano’s patented ion source for efficient production,” Petrushina noted. According to Lowe and other company executives, the system will produce over 25 different radioisotopes for cancer diagnostics and treatments starting in 2025.

Nusano’s innovation extends beyond the LINAC and ion source. Its entire production model is designed for scalability and responsiveness—an uncommon trait in nuclear medicine supply chains. “Think of it as an energy source,” said Lowe. “We actually produce that energy in a nice, micro-pulsating fashion… it literally melts like butter on toast.” The company's signature 73-foot linear accelerator—compact compared to legacy systems like California’s mile-long SLAC—is powerful enough to split into 12 separate beams, enabling simultaneous production of 12 different isotopes. “Existing technology has to plan two or three years in advance just to make one product,” Lowe said. “We can produce 12 different products at once.” Lowe hinted that the company could eventually produce “over 40, probably over 50 isotopes,” and emphasized that science is no longer the bottleneck: “It’s simply what the market wants.”

Nusano is also positioning itself as a critical player in the push for domestic isotope production. “Where does most of that material come from? Western China or Russia,” said Lowe. “By creating a domestic supply of stable isotopes, Nusano is improving national security, and enabling scientific innovation.” He highlighted technical limitations of legacy suppliers, particularly those based in Russia. “80% quality was like a home run for the product shipped out of Russia for decades. That’s a distant memory. Now it’s 99.9% or bust.” Nusano plans to continue expanding its stable isotope inventory, particularly for rare earth elements critical to medical and industrial applications.

The new building is built like a bunker encased in thick concrete. Lowe said the new Nusano facility rests on 683 massive pillars that reach 88 feet into the ground and contains an unfathomable “162,000 metric tons of concrete.” He emphasized the building’s structural integrity. “We are geologically stable in a 7.0 earthquake. The whole facility moves as one,” Lowe said. “This is the safest thing I’ve ever come across in my life.” Production of higher-security materials, such as uranium fuel, will take place at a separate location. “We will go make that out in the middle of the desert, behind walls and guns and guards,” said Lowe.

Nusano's factory and separate HQ building are elements of the emerging Medical Innovation Technology (MIT) research campus currently under development in West Valley City near the 201 Expressway and Bangerter Highway – 10 minutes from Salt Lake City International Airport. Envisioned and championed by the Wasatch Group (Salt Lake City), the MIT campus is poised to become a premier hub in Utah for medical manufacturing and innovation.

Lowe agrees. “This capability here has already attracted several other therapeutic or drug companies right here along the street,” he said. “Some of which are announced, and some of which are not announced yet. But they will be next door to us.” In closing, he was emphatic about the long-term significance: “Decades from now, we will look back and say this is the place where it all began.”

For more information, visit Nusano's website.

Scan QR code below to see how Nusano creates alpha ions at unprecedented volumes.